Service Waste, a family-owned company based in Fort Worth, Texas, has become a pioneer in the recycling and waste management industry in the region. The organization received the first UNTHA XR shredder to be commissioned in the USA almost a decade ago. Over the years, the machine has processed an average of 480 tons of commercial, industrial, and pallet waste per week, converting this locally collected residual material into an alternative fuel for the cement industry.

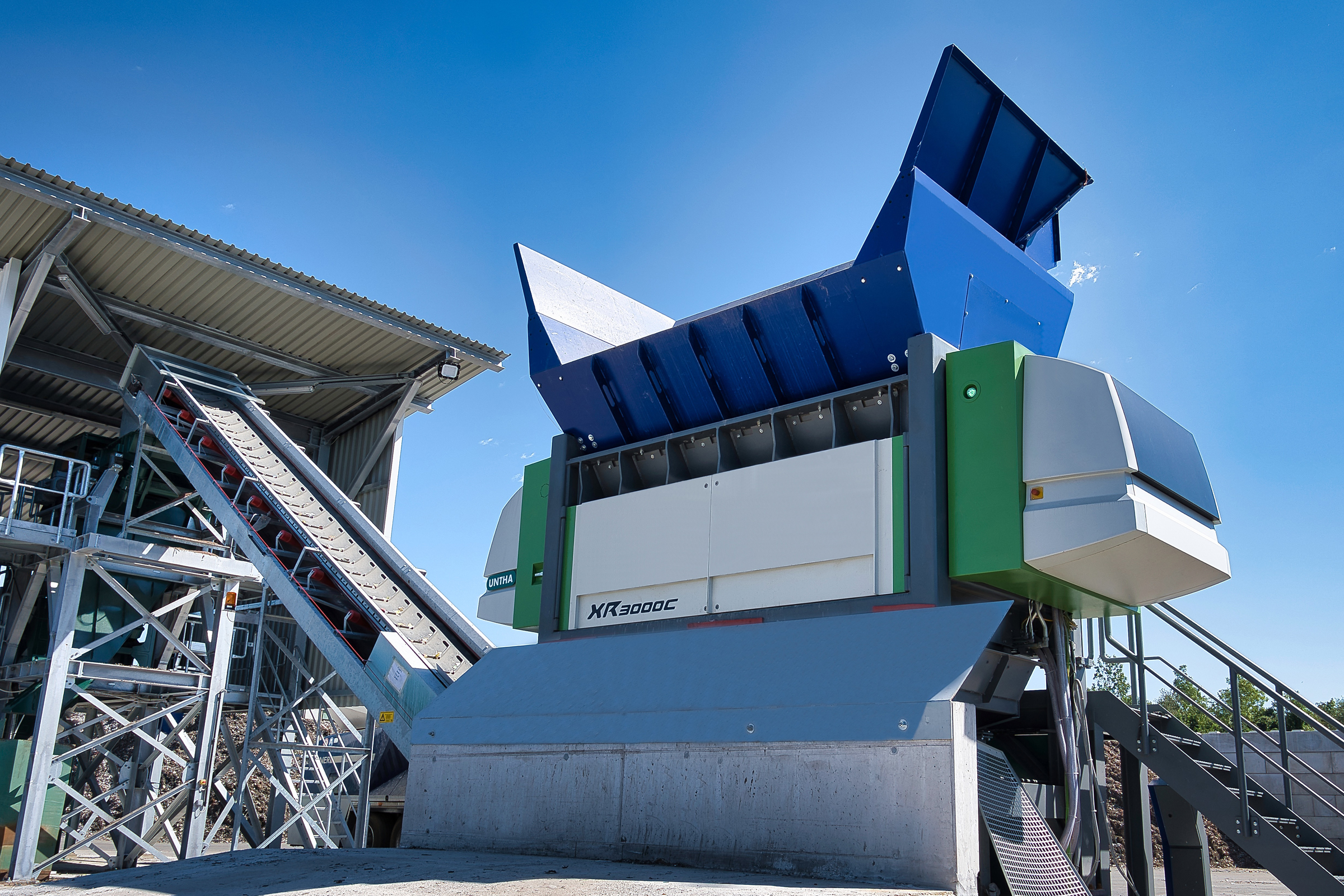

Fast forward to 2024 and with customer demand continuing to rise, Service Waste aimed to enhance its shredding capabilities once again. A new, larger 24-ton XR shredder therefore made the 5,500-mile journey from UNTHA America’s manufacturing headquarters in Austria. Following a one-week installation and testing period, the electric-driven machine is now fully operational.

The versatile machine featuring a 9’8” aperture, can easily handle a variety of challenging, bulkier input materials, and is currently configured to produce a 2¾” particle size. Built-in resistance to foreign objects such as stray metal content, protects the machine from damage allows for easy extraction of these materials. The result is a high-quality, homogenous, and “on-specification” fraction, that serves as Refuse Derived Fuel (RDF) for cement kilns.

REQUIREMENTS

High throughput and efficiency

Durability and resistance to wear and tear

Energy-efficient operation

Ability to produce homogenous output material

Low maintenance requirements

When we made the decision to invest in a new machine, returning to UNTHA was a ‘no brainer. Our criteria revolved around shredder durability, throughputs, uptime performance, operator safety, energy efficiency, and ease of maintenance. The XR ticks all the boxes – a testament to its strength and reliability.

Robert Dunlap

General Manager of Service Waste