References

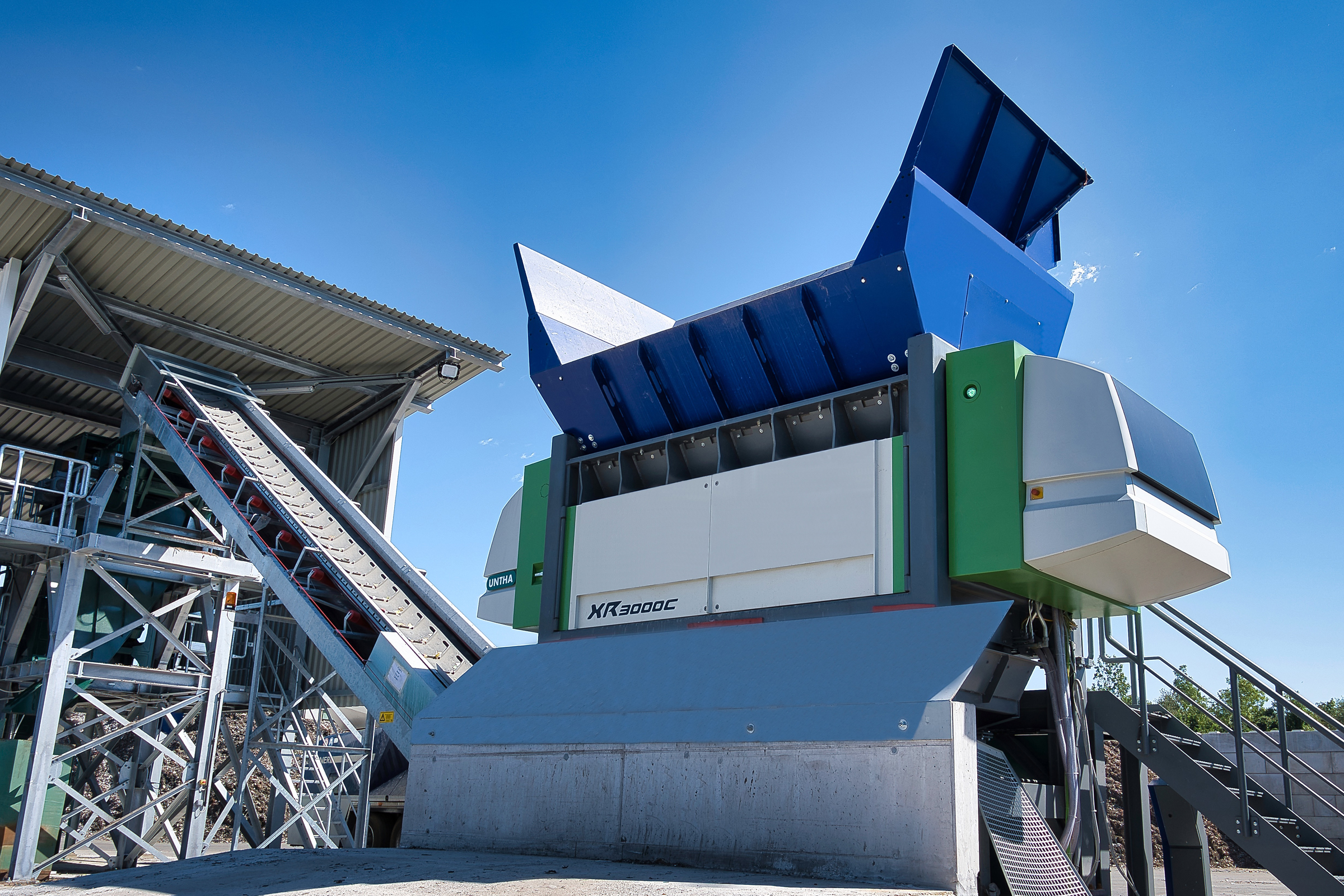

For recycling waste wood in a range of categories, Breitsamer Entsorgung Recycling GmbH in Munich puts its trust in UNTHA’s XR3000C mobil-e, thanks to the unit’s unique combination of the energy-efficient UNTHA Eco Power Drive, the high level of mobility and the option of producing different grain sizes using a single shredder.

Breitsamer Entsorgung Recycling GmbH is a waste disposal company based in Munich, with annual approved inbound quantity of 205,000 t of waste for processing and storage. In addition to the in-house sorting plant for building, commercial and production waste, the company also operates its own waste wood processing facility.

Breitsamer wanted to exchange its diesel-powered hydraulic pre-shredder for an electric-drive, mobile shredding solution. The company was looking for a single-phase processing solution for 40,000 t of waste wood per year, with a throughput of 35 t/h and a particle size of less than 120 mm. Breitsamer mostly processes A1-A3-graded waste wood, but also A4-graded wood with metal inclusions.

To fulfil the specified requirements in the best way possible, Breitsamer invested in an XR3000C mobil-e. The shredder comes with the “timber package” for single-phase waste wood processing and is particularly energy efficient, thanks to the UNTHA Eco Power Drive. The specially developed shape of the blades ensures a particularly aggressive intake behaviour for the waste wood.

The screens come with chip breakers, creating a homogeneous grain size without excess lengths. Thanks to the hydraulic quick-change screen system, the screen may be exchanged in less than 30 minutes. Wear protection surfacing ensures a long lifespan for the rotor as well as lower maintenance costs.

The shredder is so flexible that we are able to process not just grade 1 to 3 waste wood, but also grade 4 waste wood. The metal we remove from the wood is sold on to the steel industry.

Thomas Breitsamer

Managing Director

The decision in favour of the XR3000C mobil-e was taken due to its unique combination of the energy-efficient UNTHA Eco Power Drive, the high level of mobility and the option of producing different grain sizes using a single shredder. For maintenance and service, the mobile unit is taken from the machinery hall to the workshop located nearby, where all necessary works may be completed safely and with the appropriate tools. Thanks to the hydraulic quick-change screen system, the screen may be exchanged in less than 30 minutes.