Products

Your reliable shredder for plastic materials

Mature technology

Reliable, long service life

Low maintenance

Flexible utilization

Rated capacity of the rotor: 25 hp | 18.5 kW

Feed opening: 27.6" 41.3" | x 700 x 1.050 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Rated capacity of the rotor: 29 / 40 / 2 x 29.5 hp | 22 / 30 / 2 x 22 kW

Feed opening: 39.4" x 41.3" | 1.000 x 1.050 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Rated capacity of the rotor: 40 / 59 / 2 x 40 hp | 30 / 44 / 2 x 30 kW

Feed opening: 55" x 41.3" | 1.400 x 1.050 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

The reliable and sturdy LRK700, LRK1000, and LRK1400 plastic shredders are used in the plastic processing industry for regranulation, in-house recycling, and volume reduction.

Like all UNTHA shredders, the LRK plastic shredders can be used as a stand-alone

solution or integrated into complex plants. High throughputs, high availability, and particle precision guarantee the high economic efficiency of these flexible single shaft shredders for the user.

The LRK shredder can be individually adapted to any plastic shredding tasks. Different drive capacities, different rotor shapes, an effective cutting system, and a powerful swing pusher all ensure a high throughput and perfect processing and economic shredding for any plastic materials. The low-wear pusher guarantees a long lifetime for the machine and low maintenance costs for recycling companies.

The machine cutting units can be easily and quickly replaced, thereby reducing shredder downtimes to a minimum. The rugged swing pusher with its maintenance-free guide is moved by two hydraulic cylinders, which prevents jamming and further increases shredder availability.

We equip our plastic shredders with a rotor cooling system for materials with a low melting point. This makes them particularly effective regarding throughput performance.

The LRK shredders are mainly used for recycling dashboards, car interior panels, films, film rolls, cardboard, plastic barrels, PET bottles, plastic packaging, clumps, plastic pipes, waste bins, production waste, foams, car bumpers, textiles, fibers, and packaging material.

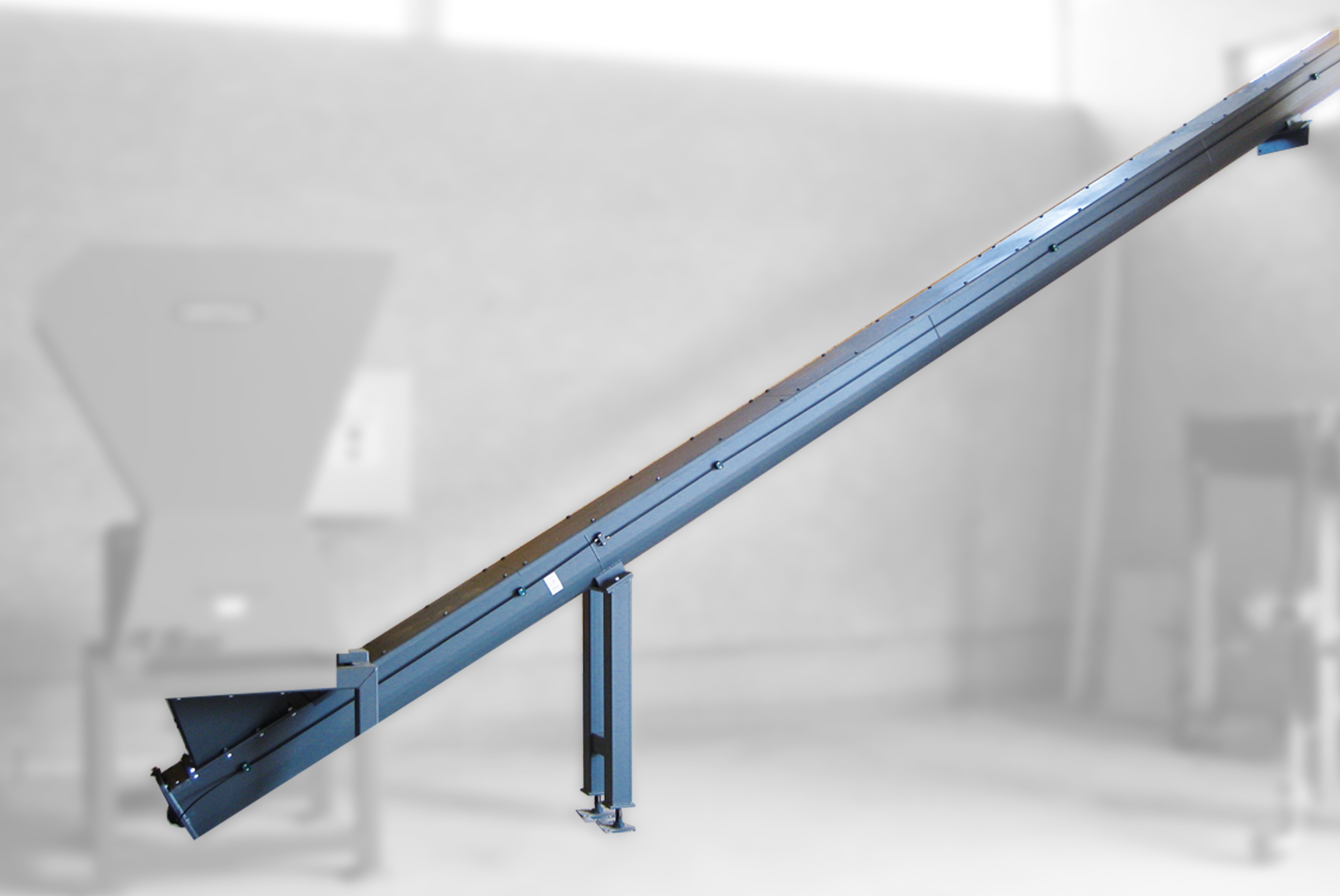

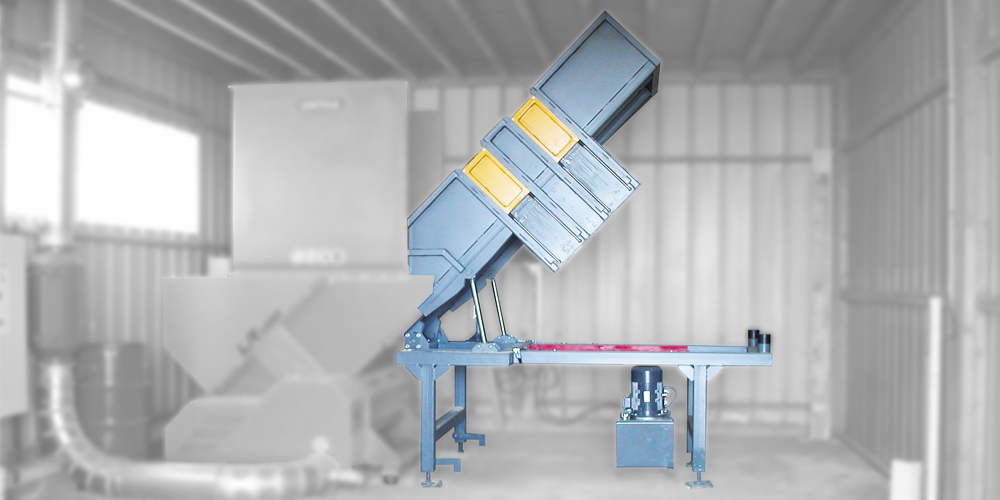

Due to its 50 years of experience in shredding technology, UNTHA offers a particularly efficient solution for plastics recycling and processing post-consumer waste with the LRK class. Each UNTHA shredder for plastics is individually configured for the intended purpose and can be adapted to the recycling requirements placed upon it using additional accessories such as a discharge screw, a rotor cooling system, special mounted hoppers, and flexible control extensions.

Rely on our expertise in plastics recycling!

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

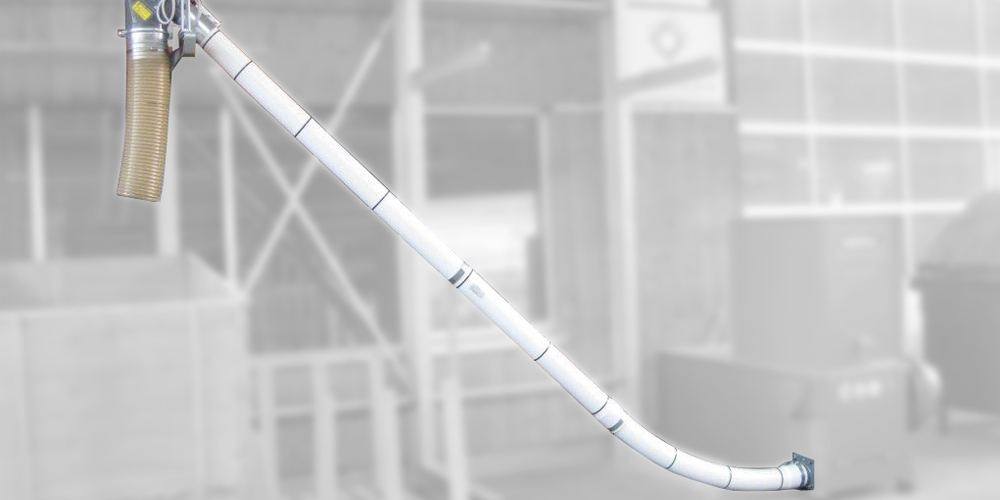

Depending on your requirements, we offer custom-made accessories for this shredder.

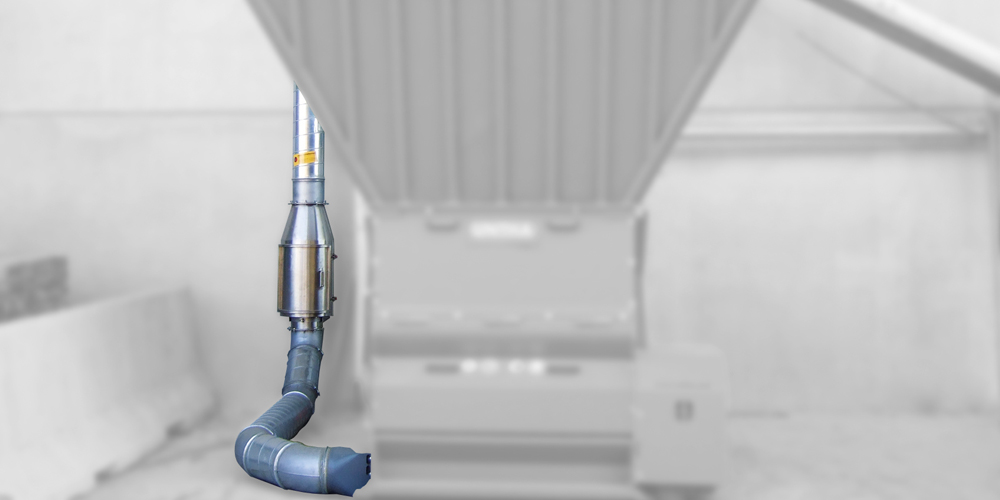

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.