Products

The powerful shredder for battery packs, metal, tires, scrap, and particularly hard applications

For particularly difficult applications

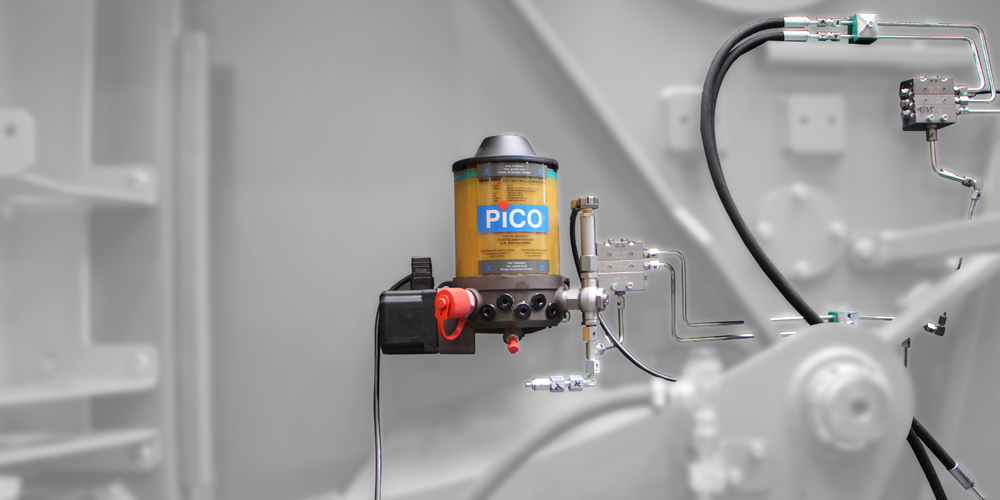

Low maintenance and high availability

Low operating costs

Rated capacity: 4 x 107 / 4 x 60 hp | 4 x 80 / 4 x 45 kW

Feed opening: 59" x 49.6" | 1.500 x 1.260 mm

Fraction sizes (based on the screen): 1.6" - 4" | 40 - 100 mm

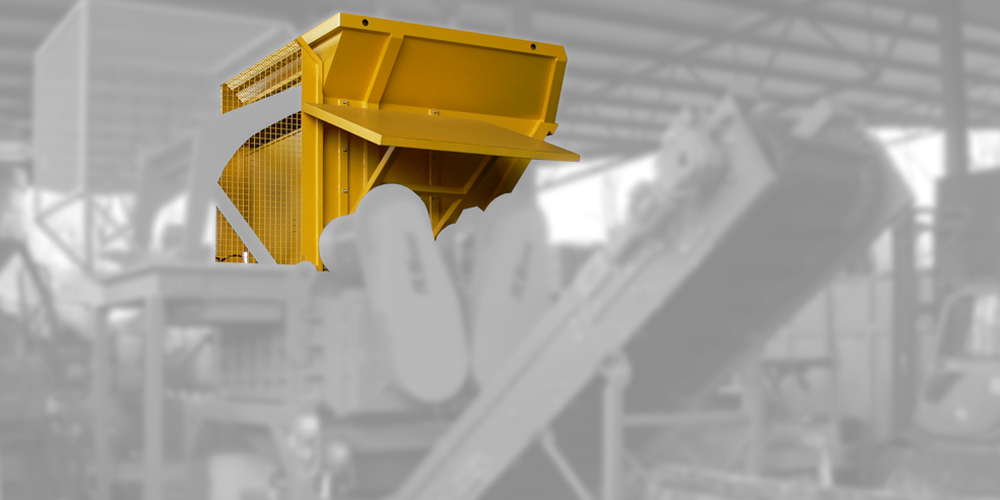

The RS150 is UNTHA’s largest four-shaft shredder and has been developed for especially tough applications where high throughput, low downtime, and low maintenance costs are required. The UNTHA exclusive water-cooled synchronous drive minimizes power consumption, with substantially higher efficiency than conventional hydraulically driven shredders.

At the heart of this incredibly tough shredder is the energy saving UNTHA Eco Power Drive. With four smaller, low rpm motors, the shredder can stop immediately when it encounters an unshreddable object to protect the cutting system and driveline without the need of clutches or couplings. This drive also permits frequent reversing, giving it the flexibility of a hydraulic system without the maintenance and energy consumption.

The variable speed drive allows you to adjust the shredder to match the material and your downstream system’s capacity. It also allows the shredder shafts to slow when shredding tough items, while still delivering full torque to the cutters. High throughput and low downtime coupled with high efficiency and simple maintenance make the RS150 a powerful and efficient workhorse for your recycling plant.

The potential applications that the RS150 can handle are nearly limitless. Our largest four-shaft shredder can handle almost any material that can be sheared.

The RS150 is ideal for shredding battery packs (lithium-ion batteries), nonferrous extrusions, castings, forgings, and sheet, as well as high-capacity electronic scrap, and filled metal barrels and IBC containers. This machine is a true powerhouse, ready for the special challenges inherent in industrial shredding.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

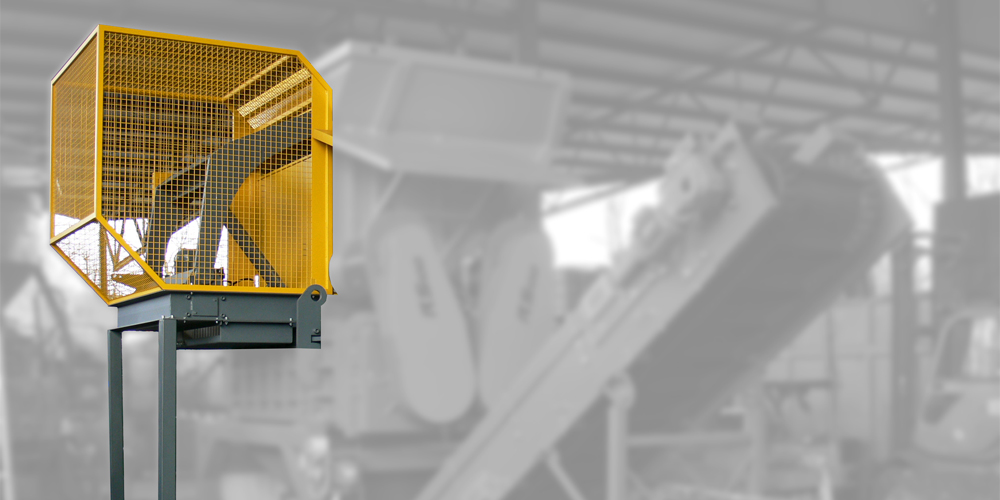

Depending on your requirements, we offer custom-made accessories for this shredder.

We are also happy to provide infeed and discharge conveyor belts. These will be optimally adapted to the on-site conditions and the desired throughput performance of the industrial shredder.