Products

Versatile shear shredders for many applications

Rugged and compact machine construction

High availability and process stability

High resistance to foreign objects

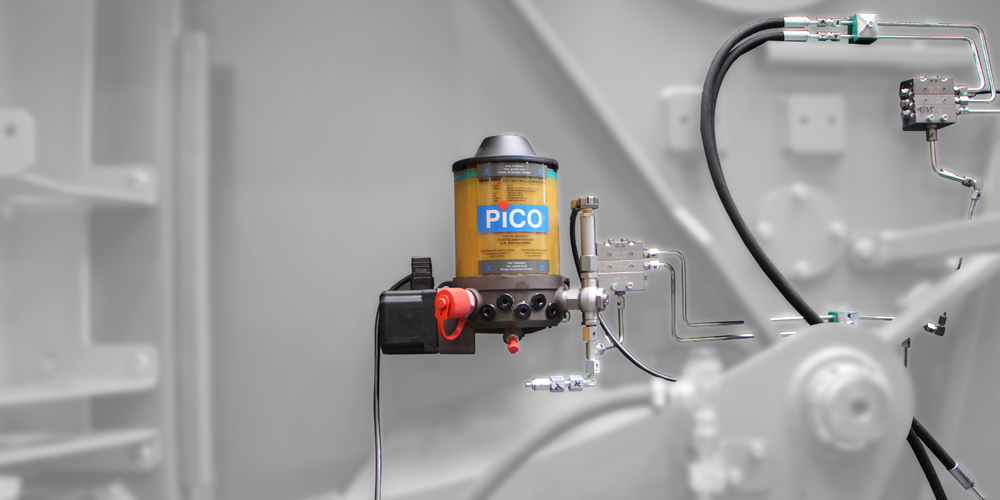

Low maintenance

Celebrate the launch of our advanced generation 4-shaft shredders! From May 13 to July 31, 2024, you will receive an UNTHA value voucher for any RS30, RS40, RS50, RS60 or RS100 shredder ordered during this time.

Rated capacity: 15 / 20 / 30 hp | 11 / 15 / 22 kW

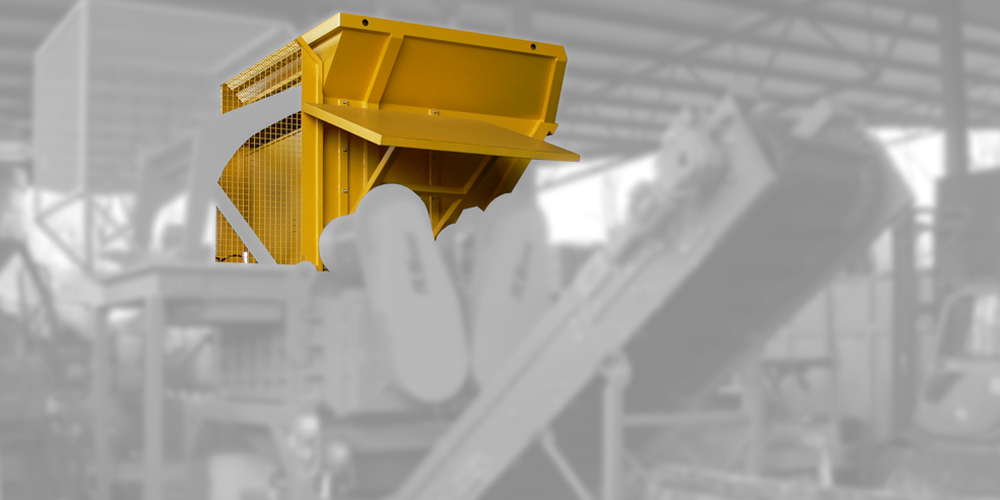

Feed opening: 17.7" x 23.6" | 450 x 600 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Rated capacity: 40 / 50 / 59 hp | 30 / 37 / 44 kW

Feed opening: 29.5" / 39.4" x 27.5" | 750 / 1.000 x 700 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Our reliable and robust RS30 and RS40 four-shaft shredders are designed for a wide range of light to moderate applications. Their compact design, long life, and low maintenance requirements make installation easy and keep your operating costs down.

The RS class four-shaft shredders are known for their low maintenance requirements and stable operation. Their simple, straightforward design has been proven over decades of service in the toughest applications.

The low speed, high torque shear shredding mechanism produces consistently high-quality particulate. Particles are homogeneous and well defined, and the shredder’s interchangeable screens allow particle size to be tailored to meet your exact requirements.

UNTHA’s unique cutter design and construction delivers extra-long life and eases maintenance by reducing wear on shafts and components. Special features make for a more stable cutting system, and extra hard cutting edges deliver long life, even when shredding tough or abrasive materials.

The RS class’s vertical feed and bottom discharge eliminate the need for a hydraulic ram, which reduces cost, maintenance and electricity usage, while the slow shaft speed reduces noise and dust generation.

Above all, the RS class shredders meet the highest industry safety standards. They are designed to automatically shut down if overloaded and particular focus is given to making them safe to operate in your facility.

Overall, the RS30 and RS40 are highly flexible machines that can be used in many light to moderate shredding applications. They are well suited to hard drive and other data destruction, medical waste shredding, document and currency shredding, and product destruction for household and smaller goods. They also have many applications in electronic scrap and PCB recycling, product Depackaging, and light metal shredding.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

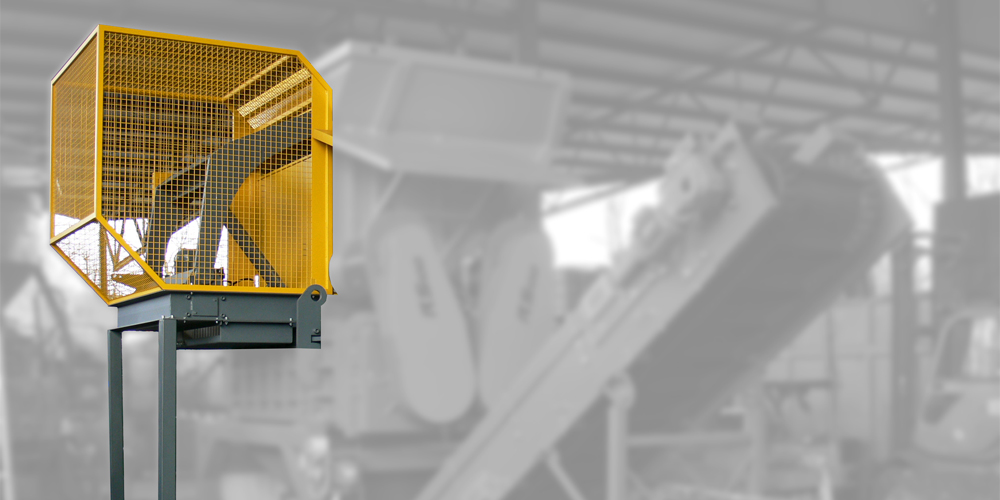

Depending on your requirements, we offer custom-made accessories for this shredder.

We are also happy to provide infeed and discharge conveyor belts. These will be optimally adapted to the on-site conditions and the desired throughput performance of the industrial shredder.