Industrial shredders: Reliable, powerful and versatility

The RS50/60/100 industrial shredders are powerful machines used to reduce the size of various materials for easier recycling and product destruction.

These four-shaft shredders are well-known in the industry for their high performance, versatility, and reliability. They can handle a wide range of difficult materials, including batteries, metals, aluminum profiles, and electronic waste down to a defined fraction size from 0.6" - 3.9" (15 to 100 mm).

For particularly difficult applications

Compact and rugged design

High availability and process stability

Low noise and dust emissions

Celebrate the launch of our advanced generation 4-shaft shredders! From May 13 to July 31, 2024, you will receive an UNTHA value voucher for any RS30, RS40, RS50, RS60 or RS100 shredder ordered during this time.

Rated capacity: 59 / 67 / 80 hp | 44 / 50 / 60 kW

Feed opening: 29.5" / 39.4" / 48.4" x 27.5" | 750 / 1,000 / 1.230 x 700 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Rated capacity: 80 / 100 hp | 60 / 74 kW

Feed opening: 39.4" / 47.2" / 56.7" x 33.9" | 1,000 / 1.200 / 1.440 x 860 mm

Fraction sizes (based on the screen): 0.8" - 4" | 20 -100 mm

Rated capacity: 147 / 201 hp | 110 / 150 kW

Feed opening: 47.2" / 59" x 40" | 1.200 / 1.500 x 1.020 mm

Fraction sizes (based on the screen): 0.8" - 3.9" | 20 - 100 mm

Top-quality recycling machines for the toughest applications and materials from Europe’s premier shear shredder manufacturer: The venerable RS50, RS60, and RS100 four-shaft shredders have proven themselves over the years to be tough and reliable partners in your business. Rugged UNTHA designed gear systems allow you to shred for long hours without a break and long maintenance intervals give you maximum uptime. The shredders’ low noise and dust levels make them easy to live with and their compact footprint makes it simple to fit them in to your existing layout.

Designed to increase your profitability

These midsize shredders’ modular design enables UNTHA to configure your shredder to best suit your application. Multiple cutting lengths, cutter sizes, gear ratios, seals, and screens mean that you don’t have to compromise. The rugged construction and long maintenance intervals make the RS series particularly attractive for ‘round-the-clock operation and for improving your current plant's productivity.

As opposed to typical faster-turning single shaft shredders, the four-shaft shredder's lower tip speeds and more robust cutters can better handle foreign objects. If an unshreddable item gets into the shredder, the machine stops immediately, reducing the chance of damaging the shredder. The heavy-duty shredder is also able to reverse one shaft set at a time, helping it to chew through extra tough pieces.

The quick screen change system enables fast screen changes and cleaning, helping to maximize your productivity.

These midsize four-shaft shredders are well suited for shredding electronic scrap, paper, medical waste, batteries, appliances, plastic, etc. The RS100 can also be configured to shred IBC containers and steel barrels.

Controls can be configured with VFD drives, heating and cooling, and controls for material handling equipment, allowing the shredder to control your entire line from a single PLC.

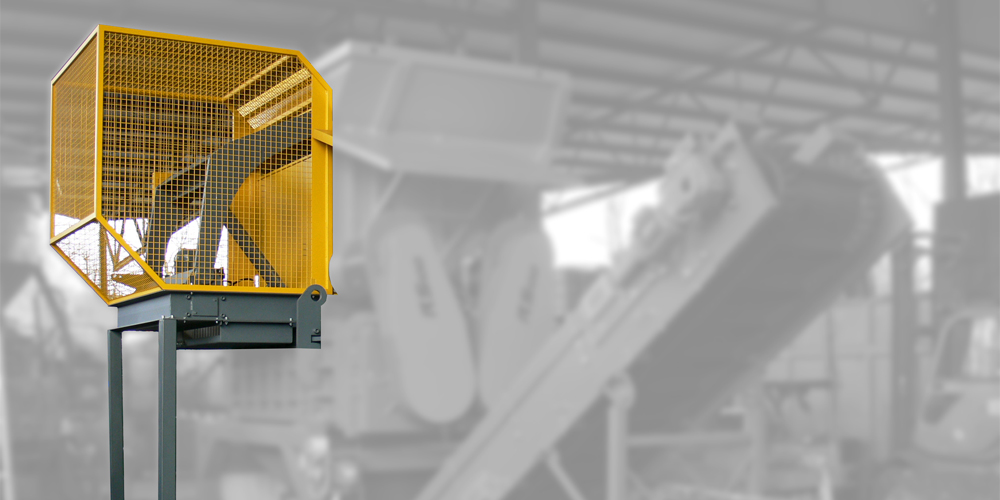

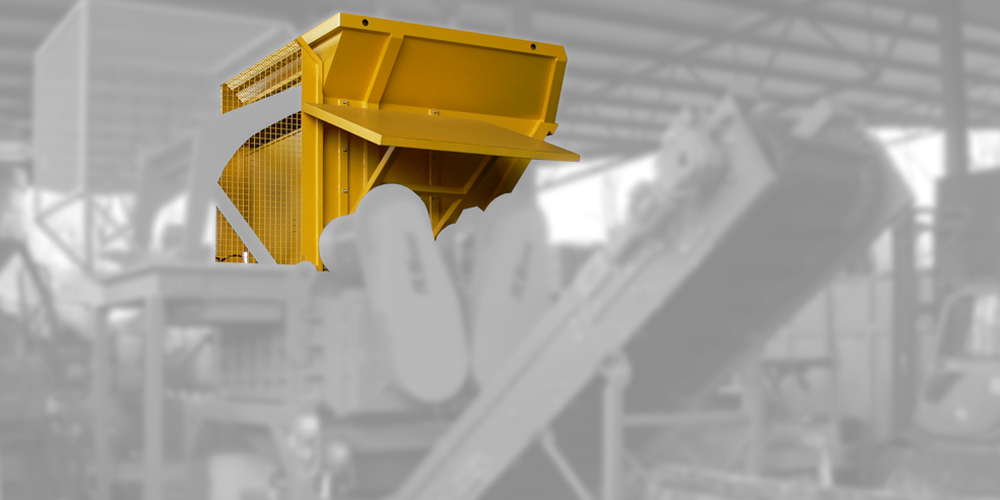

Hoppers and stands can be customized to fit with your existing material handling and separation equipment, and you can usually fit a larger industrial shredder into the space formerly occupied by a smaller shredder from a different brand.

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

Depending on your requirements, we offer custom-made accessories for this shredder.

We are also happy to provide infeed and discharge conveyor belts. These will be optimally adapted to the on-site conditions and the desired throughput performance of the industrial shredder.