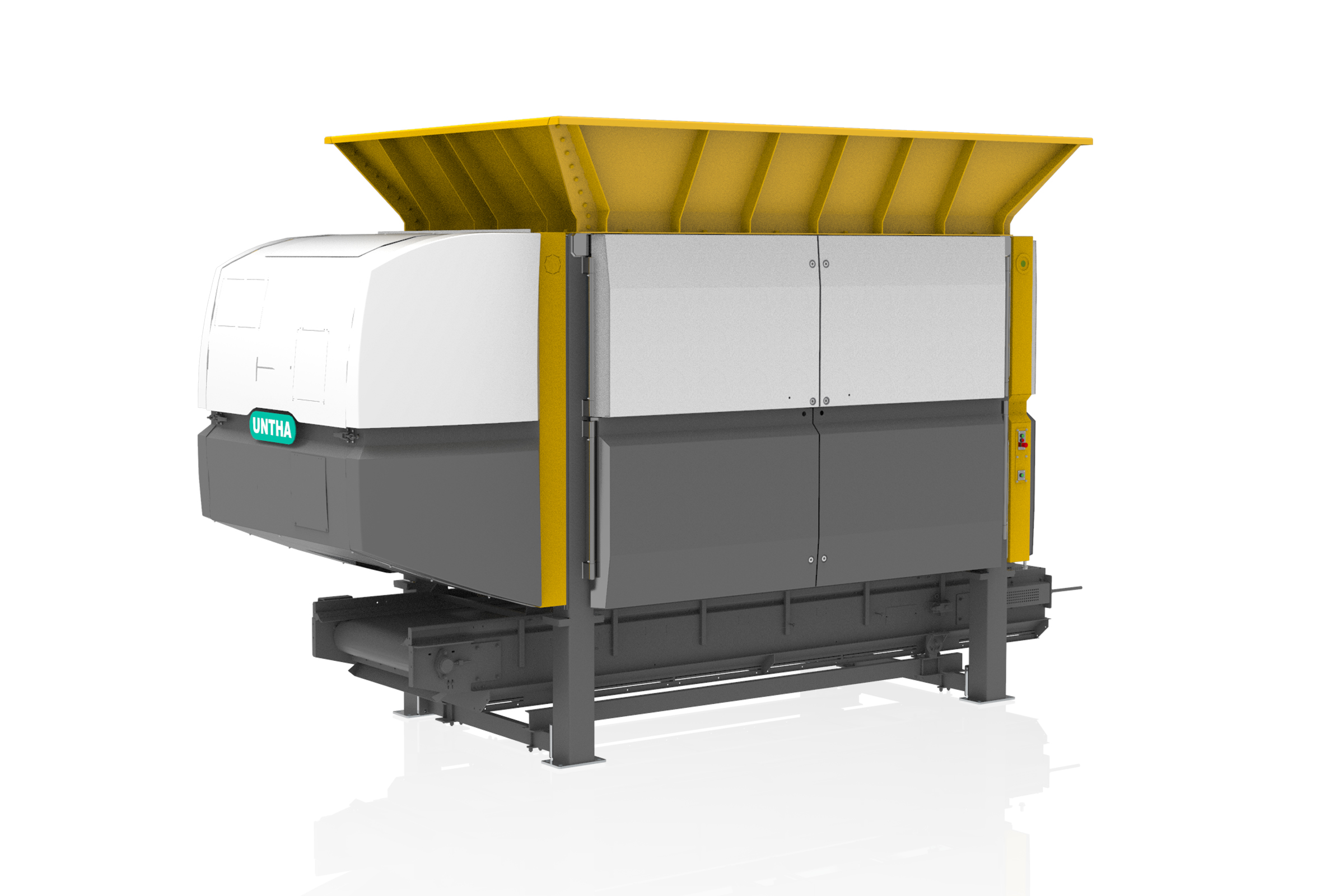

Powerful pre-shredder

The ZR is a powerful pre-shredder for the rough shredding of high-volume waste and recyclables. The low-speed, high-torque two-shaft shredder pre-chops different waste materials like C&D debris, municipal solid waste (MSW), bulky waste, wood waste, and metal scrap into smaller, more manageable pieces. This volume reduction makes it much easier for sorting, storage, and transportation.

Ultra energy efficient thanks to UNTHA Eco Power Drive

A versatile machine for different materials

Easy and fast cleaning of the cutting chamber

Quick table change system

Easy maintenance

Impressive throughputs and homogenous outputs

Primary shredder with high throughput

Driving power: 2 x 177 hp | 2 x 132 kW

Rotor diameter: 35.4" | 900 mm

Maximum throughput capacity: 100 t / h

Fraction sizes: 90 % < 11.8" | 90 % < 300 mm

The power-saving UNTHA Eco Power Drive contributes significantly to the economical operation of the ZR shredder with the lowest life-cycle costs in its class. The energy-efficient electric drive with a water-cooled synchronous motor consumes up to 75 percent less energy than a conventional diesel-hydraulic drive.

Two different cutting systems make the ZR a machine for varied materials.

The cutting chamber of the ZR is easily accessible and can be cleaned quickly, safely, and efficiently.

Thanks to the UNTHA quick-change cutting system, both the H and the W cutting systems of the ZR may be removed and replaced by a new unit within no time.

Cutting shafts that run independently of each other ensure perfect material disintegration.

Thanks to the UNTHA GENIUS condition monitoring system, machine utilization can be significantly increased.

The ZR2400 pre-shredder

With the ZR class, we have developed the most economical 2-shaft shredder with the lowest life-cycle costing (LCC) in its class.

Advantages of the ZR2400 pre-shredder

The powerful pre-shredder with the energy-efficient UNTHA Eco Power Drive system delivers high throughputs and excels when processing difficult-to-shred waste and recyclable materials. The machine’s robust and resilient construction is designed for multi-shift continuous operation. The quick-change table system and the simple design guarantee high plant availability. The powerful, slow-running and ripping cutting system is enormously resistant to impurities and ensures perfect material preparation for sorting plants. This machine class is perfectly configured for reducing volume or producing alternative fuels. The primary srhedder comes with two different cutting systems for varied material handling.

The stationary ZR is designed for coarse shredding of different materials and is exceptionally economical in tough continuous operation. The use of future-oriented technology results in extremely low life-cycle costs for the operator. This makes the ZR a reliable powerhouse of a shredder that makes great economic sense: TOUGH performer, SMART saver.

These materials can be shredded with the ZR2400:

With UNTHA GENIUS, we are giving our customers an innovative tool for monitoring the condition of their shredders on an ongoing basis. Using reliable sensor technology, this intelligent monitoring system processes all data in real time, alerts users of deviations, and sends decision support directly to your smartphone, tablet, or PC.

With the H and W cutting systems, the stationary ZR2400 offers two different cutting systems for a wide range of materials.

The H-shredding system is used for coarse processing (90 % < 300 mm) of household waste, bulky waste, commercial and industrial waste, waste wood, mattresses, carpets, mixed construction waste, railway sleepers, baled goods, and rolled goods. The aim of shredding is to reduce the volume, to produce RDF, and to break down the material for downstream processing.

UNTHA’s shredding technology is renowned globally. The new ZR shredder has also already had the opportunity to demonstrate its qualities impressively.

We were surprised at the fantastic results with regard to energy input in particular. Compared to other manufacturers, we are talking about energy savings worth 70,000 Euro a year as a result of using the ZR!

Hubert A. Schwarz

Head of Processing and Process Development

From commissioning to hard surfacing, cutter changes, and regular inspection and maintenance activities, we look after your industrial shredder throughout its lifetime.