Products

The powerful wood shredder for pallets and bulky materials

High throughput capacity

Reliable

LR technology package included

Homogeneous wood chip quality

Customized system solutions

Rated capacity: 29.5 / 40 / 2 x 25 hp | 22 / 30 / 2 x 18.5 kW

Feed opening: 39.4" x 41.3" / 63" | 1,000 x 1,050 / 1,600 mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Maximum throughput capacity: 8 srm/h

Rated capacity: 40 / 2 x 29.5 / 2 x 40 hp | 30 / 2 x 22 / 2 x 30 kW

Feed opening: 55" x 41.3" / 63" | 1,400 x 1,050 / 1,600* mm

Fraction sizes (based on the screen): 0.6" - 1.6" | 15 - 40 mm

Maximum throughput capacity: 10 srm/h

LR1000 and LR1400 are the largest UNTHA LR shredders, and therefore particularly suitable for carpentries and sawmill plants and for the wood working industry, where large quantities of waste wood are accumulated. These two powerful machines are mainly used for demanding shredding work, for which high throughputs are required. The wood shredders are able to develop their full performance capacity from waste wood quantities of 12 m³ per week. Thanks to their size, these machines are the ideal shredders for pallets and bulky pieces of wood.

The strong throughput capacity of the LR1000/1400 shredders is a result of the strong drive motors and the performance-oriented machine configuration. The configuration includes a long rotor, a large perforated screen surface and optimized cutter geometry, performs the way you need it to in your plant. High performance requires reliable machine operation, which we ensure with a full range of high-quality technological components.

Thanks to the rotor's special mounting, dust-protected bearings, tried and trusted gear damping, and special cutting tools, the wood shredder is also low maintenance and has a long service life. The intelligent drive control shuts the shredder motor down automatically in case foreign objects enter the machine. In addition, the shredder has been equipped with an automatic reverse function to prevent motor overload.

Energy-efficient technology is particularly important for machines used in continuous operation, especially for shredding pallets. For this reason, the LR1000/1400 shredders use cutting tools with a specific blade design which can shred whilst consuming little energy. In addition, the motor shuts down automatically if no material is fed into the machine for more than three minutes. This saves energy whilst simultaneously reducing operating costs.

The LR1000/LR1400 shredders are mainly used for shredding hardwood, softwood, OSB board, chipboard, MDF sheets, veneers, off-cuts, construction timber and pallets. The homogeneous end-product produced by the shredder is ideal as high-quality wood chips for incineration in a wood chip heating system, or for manufacturing wood briquettes.

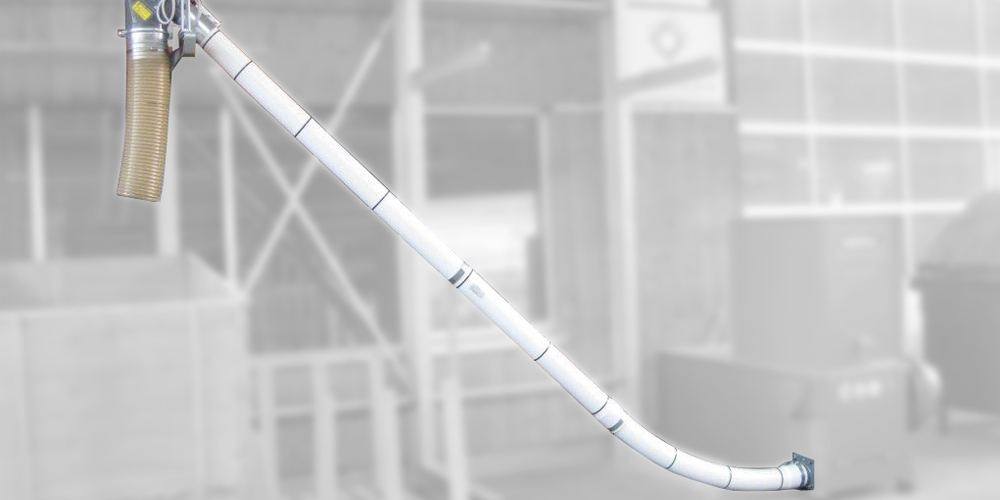

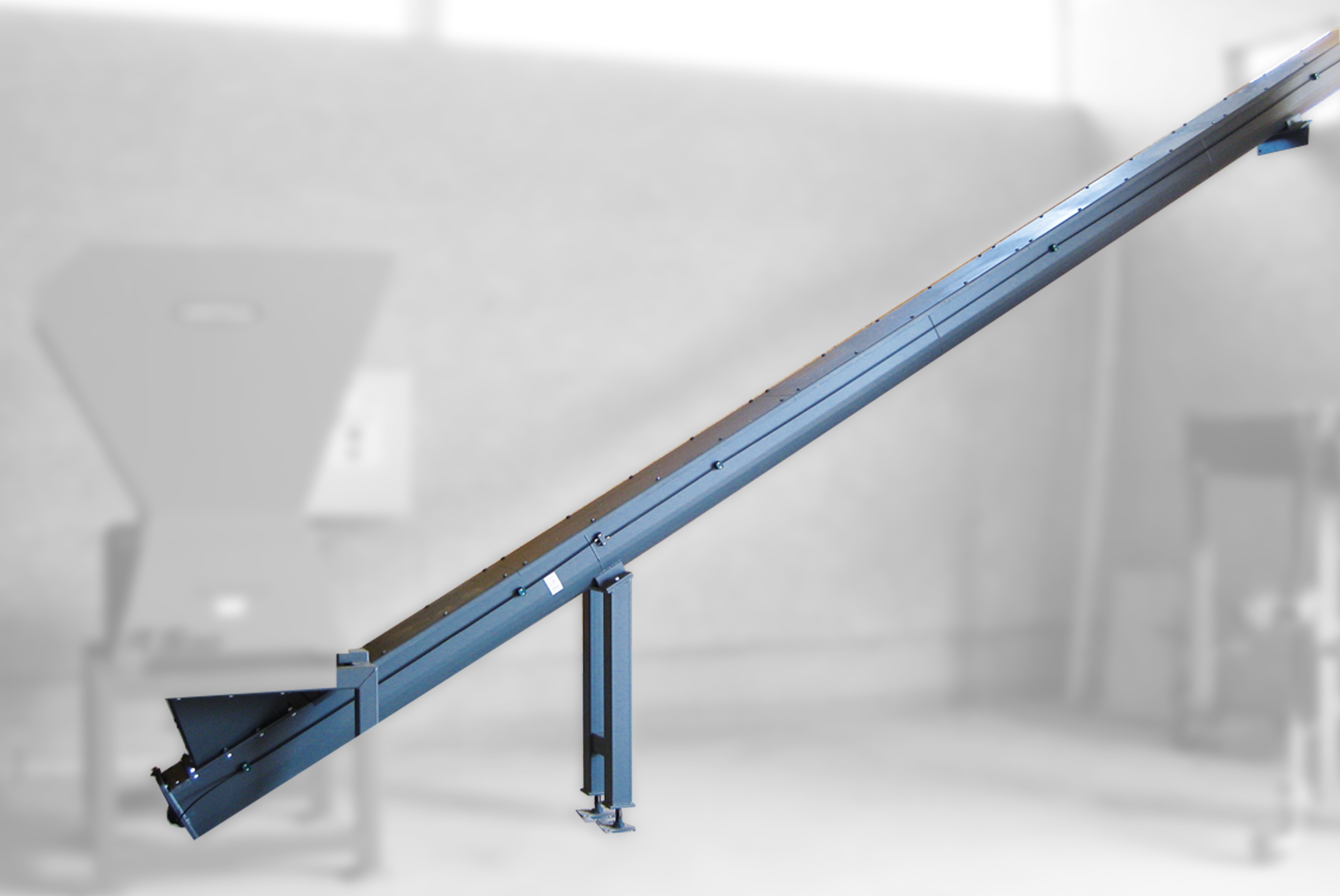

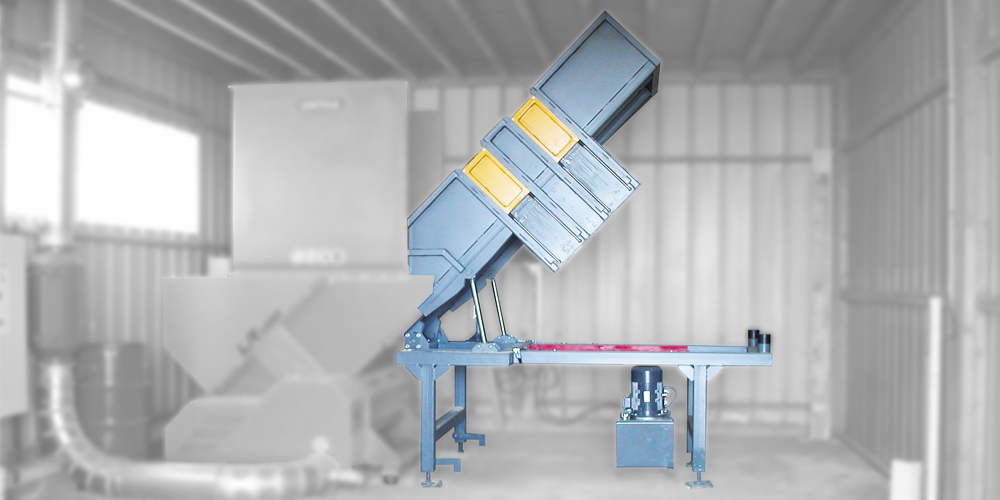

Like all machines in the LR series, the LR1000/1400 wood shredders can be adapted individually to your requirements with peripheral devices such as discharge screws, conveyor belts, metal separators or pipe magnets. We offer comprehensive, single-source solutions!

Test our shredders in the UNTHA test centre! Try our shredders in real-life conditions using your own materials. This way, you can make sure that we fulfil your requirements 100%.

Depending on your requirements, we offer custom-made accessories for this shredder.

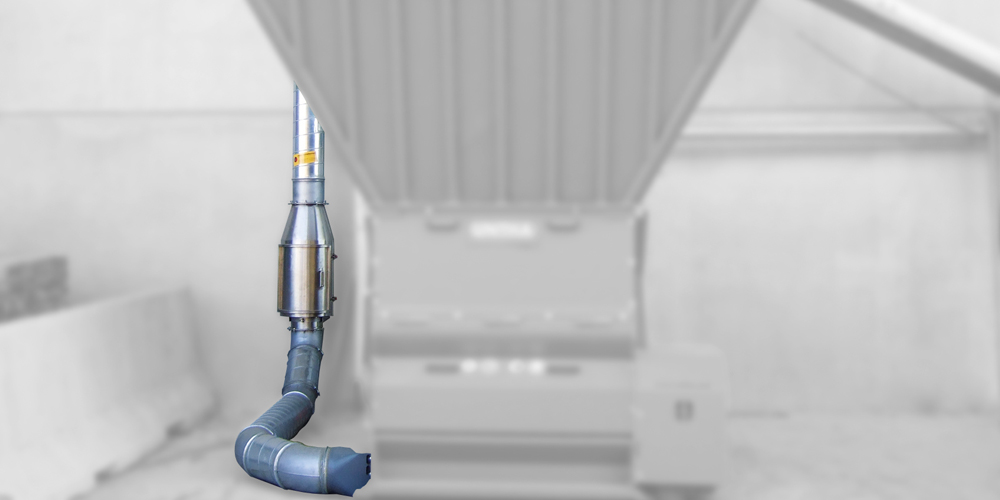

Shredding residual timber with nails or screws is no problem for our shredders. Pipe magnets are commonly used in extraction situations to separate metal pieces from the wood. We can offer you different pipe magnets depending on your application.